DIY Steel Building Assembly Guide

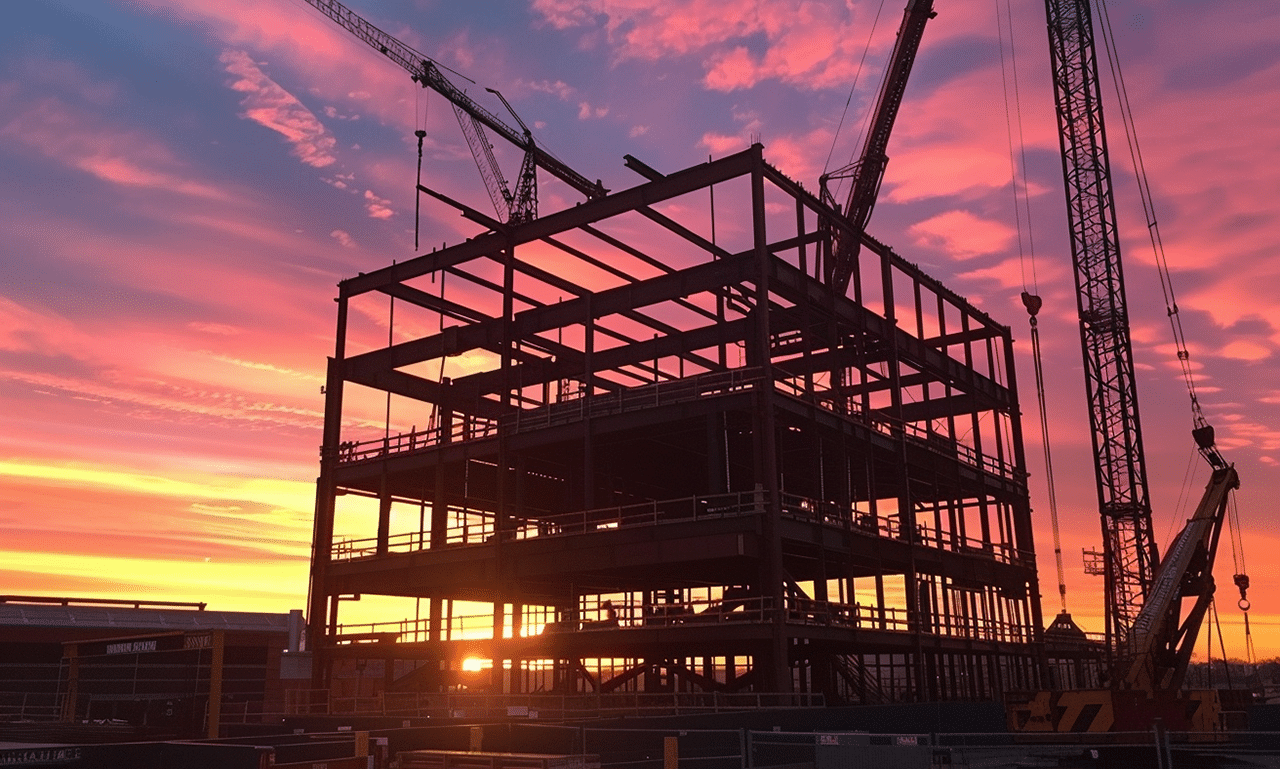

Building your own steel structure can be a rewarding and cost-effective project, whether you’re constructing a small garage, workshop, or larger commercial building.

Home

Steel Building Maintenance Guide

Building Insulation

DIY steel building assembly allows you to customize your space while saving on labor costs. This guide will walk you through the key steps and provide essential tips to ensure your steel building project is successful.

1. Why Choose DIY for Your Steel Building?

Opting for a DIY steel building project offers several advantages:

- Cost Savings: One of the most significant benefits of DIY assembly is the reduction in labor costs, as hiring professional contractors can be expensive.

- Customization: Building it yourself allows you to oversee every detail and customize the project to suit your exact needs.

- Hands-On Satisfaction: There’s a sense of accomplishment in completing the building yourself, especially if you enjoy working on construction projects.

2. Tools and Equipment You’ll Need

Before beginning your DIY steel building assembly, it’s essential to gather the right tools and equipment. Having everything on hand will save time and ensure the process goes smoothly. Here’s a basic list of what you’ll need:

- Wrenches and Ratchet Set: Essential for tightening bolts and fasteners.

- Power Drill: A power drill with the appropriate bits will help with assembling panels and frames.

- Measuring Tape and Level: Ensure your building is square and level throughout the assembly process.

- Ladders or Scaffolding: Depending on the height of your building, you’ll need ladders or scaffolding to safely reach the roof and upper walls.

- Safety Gear: Gloves, safety glasses, and hard hats are essential for protection during assembly.

Learn more about steel building types and assembly options in our Steel Building Kits section.

3. Pre-Assembly Planning

Proper planning is key to a smooth assembly process. Before you begin, follow these steps to prepare:

A. Site Preparation

Ensure your building site is ready before the steel materials arrive. Your site should be level, clear of debris, and properly graded to allow for drainage.

- Foundation: Depending on your location and the type of building, you may need a concrete slab or footings in place before assembly begins.

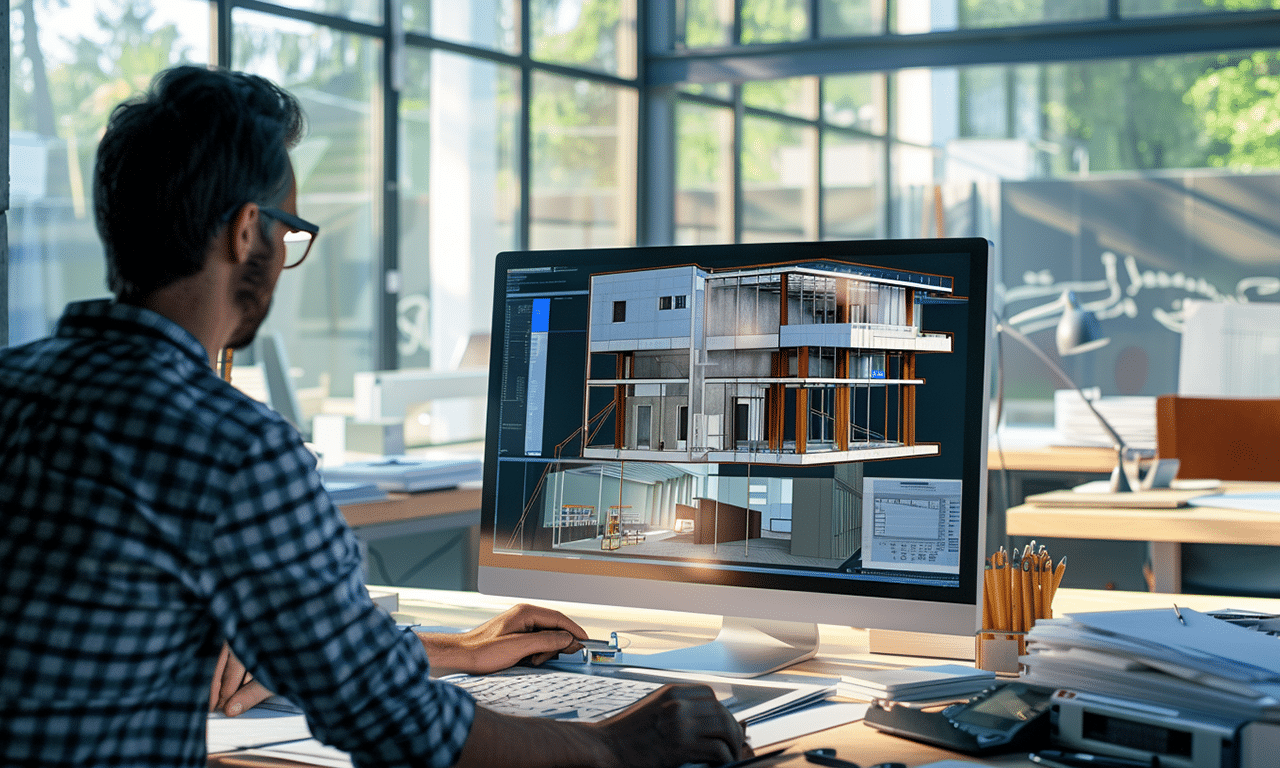

B. Review the Building Plans

Review your building plans thoroughly. The plans will detail the layout of the structure, and it’s important to understand the assembly sequence.

- Label the Parts: Take inventory of all the parts and label them according to the building plans. This step will make the assembly process more efficient.

C. Weather Considerations

Choose a period with good weather conditions to start your project, especially if working on the roof or other areas exposed to the elements.

Visit our Permits and Local Building Codes Guide to ensure your project complies with local regulations.

4. Step-by-Step Assembly Process

The assembly process for steel buildings typically follows a set sequence. Below are the general steps involved:

A. Assemble the Frame

Start by assembling the steel frame, which includes the columns, rafters, and beams. The frame forms the skeleton of your building, and it’s critical that this step is done carefully to ensure the building is square and level.

- Anchor the Columns: Secure the columns to the foundation using the anchor bolts.

- Install the Beams and Rafters: Attach the beams and rafters to the columns to complete the basic framework.

B. Install the Wall Panels

Once the frame is assembled, you can begin attaching the wall panels. Make sure each panel is securely fastened to the frame using the provided hardware.

- Insulation: If you’re planning to insulate your building, this is the stage where insulation materials, like fiberglass or spray foam, should be installed between the wall panels and the frame.

For more information on insulation options, visit our Steel Building Insulation Guide.

C. Attach the Roof Panels

With the walls in place, it’s time to install the roof panels. This step may require extra help due to the height and size of the panels.

- Weather Seals: Ensure that the roof panels are properly sealed to prevent leaks. Install flashing and weatherproofing materials to protect the roof from rain, snow, and wind.

D. Install Doors and Windows

The final step is to install any doors and windows you’ve chosen for the building. Follow the manufacturer’s instructions for proper installation and weatherproofing.

- Roll-Up Doors: If your building has large garage-style doors, be sure they are properly aligned and functioning before completing the project.

-

30×50 Metal Building MB212305014W0 Deposit

$18,000.00 Add to cart -

30×50 Garage Package Deposit

$8,500.00 Add to cart -

30×30 Garage Package Deposit

$8,500.00 Add to cart -

20×40 Garage Package Deposit

$5,500.00 Add to cart -

60×80 Steel Building Kit Deposit

$20,000.00 Add to cart -

50×100 Steel Building Kit Deposit

$20,000.00 Add to cart -

50×80 Steel Building Kit Deposit

$20,000.00 Add to cart -

50×60 Steel Building Kit Deposit

$20,000.00 Add to cart

5. Common Mistakes to Avoid in DIY Steel Building Assembly

As with any DIY project, there are a few common pitfalls to avoid when assembling a steel building:

- Skipping the Foundation Check: Always ensure that your foundation is level and properly cured before starting assembly. A poor foundation will lead to structural issues later on.

- Not Following the Building Plans: Deviating from the building plans can result in costly mistakes. Stick to the instructions provided, as they are designed to ensure structural integrity.

- Over-Tightening Fasteners: While it’s important to secure bolts and fasteners tightly, over-tightening can strip threads or damage the building materials.

- Ignoring Safety Precautions: Never skip safety gear or rush the process. Take your time and follow all safety guidelines to avoid accidents.

6. Final Inspections and Finishing Touches

After assembling your steel building, it’s essential to conduct a thorough inspection before declaring the project complete. Here’s what to check:

- Structural Integrity: Ensure that all components are securely fastened and the building is square and level.

- Weatherproofing: Check for any gaps or areas that might allow moisture to seep in and seal them appropriately.

- Final Touches: Add any finishing touches like trim, gutter systems, or paint, depending on your building’s design.

Explore more tips on keeping your building in top shape with our Steel Building Maintenance Guide.

Residential Construction

Your dream home or residential steel building project is in good hands with us.

Commercial Construction

From warehouses to office spaces, we manage the design, construction, and ...

Custom Building Projects

Tailoring every aspect to your vision, our Building Projects service delivers unique steel structures

7. When to Call in the Professionals

Although DIY assembly can be a cost-effective and rewarding option, there are times when professional assistance may be necessary:

- Complex Projects: If your building design includes complex features like mezzanines, custom layouts, or multi-story structures, it may be best to hire a professional crew.

- Limited Time or Resources: DIY assembly can take time, especially for larger buildings. If you’re on a tight schedule or lack the resources to complete the project, professional help can save time and effort.

For professional assistance, explore our Full-Service Turnkey Steel Buildings options.

Describe Your Project

Share your project details, and we’ll assign you an expert to provide tailored advice and guide you through the next steps.

Step 02

Get a Tailored Quote

Based on your project requirements, we’ll provide a customized quote that includes design, materials, and any additional services you may need.

Questions - Approvals

Review the project plan and design we propose. Once you approve, we’ll finalize the timeline and prepare everything to start the process.

Start Building

Our skilled professionals will begin the construction process, delivering high-quality workmanship and keeping you informed every step of the way.

FAQ’s

What are the benefits of choosing a steel building

Steel buildings are durable, cost-effective, energy-efficient, and customizable for a variety of uses, from residential to commercial projects.

How long does it take to complete a steel building project?

The timeline depends on the project’s size and complexity, but most steel building projects can be completed faster than traditional construction.

Do you offer custom designs for steel buildings?

Yes, we provide fully customized steel building designs to meet your specific needs, whether residential, commercial, or industrial.

Are steel buildings energy-efficient?

Yes, steel buildings can be designed with insulation, reflective materials, and energy-efficient features to reduce operational costs.

DIY steel building assembly is a great way to take control of your project, reduce costs, and customize your space. With careful planning, the right tools, and attention to detail, you can successfully construct your steel building and enjoy the satisfaction of a job well done.

If you need assistance with any part of the assembly process, or if you’re interested in professional installation services, Contact Us or explore our Steel Building Kits for more information.

Your Building Project, Simplified

- Clear, upfront pricing

- Thorough evaluation to ensure the best value for your investment

- Flexible customization options

- Fast delivery times

- Expert guidance to keep you fully informed at every step

Contact