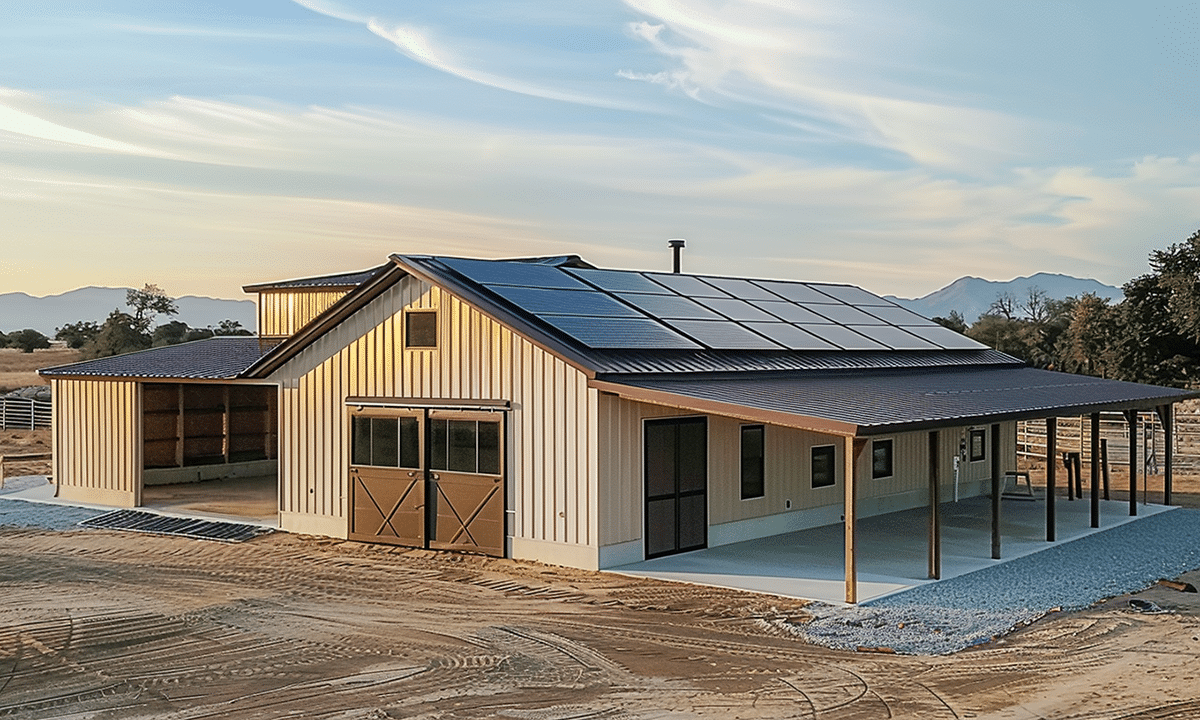

When it comes to assembling a DIY steel building, the excitement of creating a custom space for your needs can sometimes overshadow crucial details. DIY steel buildings offer an affordable and flexible solution for various applications, from barns and garages to workshops and homes. However, without proper planning and execution, common mistakes can lead to costly and time-consuming setbacks. Let’s explore some of these potential pitfalls in DIY steel building assembly and how to avoid them.

Planning and Permitting: The Foundation of Success

Before you even think about breaking ground, having a comprehensive plan and all necessary permits in place is essential. One of the first common DIY mistakes is skipping this crucial step. Without proper planning, you might face unexpected hurdles that could halt your project. Be proactive and reach out to your local authorities to determine what permits and regulations apply in your area.

A detailed plan will also help you envision the end result and identify potential challenges in advance. Consider creating a timeline and budget to ensure you have a clear path to follow throughout the process.

Choosing the Right Site and Preparing It Properly

Site selection and preparation significantly impact the long-term stability of your steel building. It’s vital to choose a site that is level and has proper drainage. Neglecting this can lead to foundation issues and water damage over time. Clear the site of any debris, vegetation, or obstacles and compact the soil to create a solid base.

Invest time in measuring and marking the site accurately, as errors here can lead to alignment issues later. Remember, precision at this stage will save you a headache in the long run.

Understanding Your Building Kit: What’s in the Box?

Once your site is ready, it’s time to dive into your building kit. A common DIY steel mistakes are failing to thoroughly review the components and instructions included. Familiarize yourself with everything in the kit before assembly begins. Ensure all parts are present, undamaged, and match the inventory list provided by the manufacturer.

Assembly can seem daunting if you haven’t built a steel structure before, but breaking down the process step-by-step can simplify things. Consider the parallels with assembling a puzzle—having a clear picture of the outcome helps guide you as you piece it together.

Getting the Right Tools for the Job

Before you start the actual construction, ensure you have all the necessary tools. These include basic tools like wrenches and hammers, as well as more specialized equipment such as drills and levels. For a comprehensive list, check out the DIY Steel Building Tools guide.

Using the right tools not only speeds up the process but also enhances the safety and structural integrity of your build. Take time to inspect and acquaint yourself with each tool for maximum efficiency and safety.

Assembly: Step-by-Step, Brick by Brick

With everything in place, it’s time to start assembling. This is where patience and attention to detail play a critical role. Let’s break down a few assembly challenges and how to tackle them effectively.

Aligning and Anchoring Frames

Alignment issues are one of the most frequent problems encountered during DIY Metal Building Construction. Misaligned frames can compromise the integrity of the entire structure. Begin by ensuring all components are aligned according to the manufacturer’s specifications. Use levels and check alignments at every stage of the assembly.

Anchoring the frames securely to the foundation is another crucial aspect. Neglecting to anchor properly can lead to instability, particularly in high-wind areas. Always follow the guidelines provided in the CISC Handbook of Steel Construction.

Sealing and Insulating the Building

Effective sealing and insulation can often be overlooked. Steel structures are prone to condensation, which can lead to rust and other issues over time. Proper sealing using high-quality weatherproof materials will help prevent these problems. Additionally, consider investing in insulation to maintain a comfortable internal climate and improve energy efficiency.

For more on avoiding common mistakes and best practices, explore our DIY Assembly Best Practices.

Preventing Costly Errors: The Devil is in the Details

Pay attention to any fine details that could lead to costly errors. It’s easy to assume you’re using the right component only to discover an error at a more advanced stage of assembly. Double-check component placement and fasteners as you work.

Frequently Asked Questions: Addressing Common Concerns

Many DIY enthusiasts have general inquiries when taking on steel building projects. Addressing Common DIY FAQs might save you from unnecessary complications. Remember, there is no such thing as a silly question when it comes to ensuring safety and accuracy.

Conclusion: Building Your Dream with Confidence

Assembling a DIY steel building can be a rewarding experience that adds value to your property. By planning ahead, preparing adequately, and paying close attention to detail, you can sidestep common pitfalls. By avoiding these DIY steel mistakes, you can ensure that your project is completed efficiently and to a high standard, gaining you the space you desire without unnecessary setbacks. Happy building!