When embarking on a construction project, selecting the appropriate steel framing system can be both an exciting and daunting decision. The right choice can ensure structural integrity, cost-effectiveness, and even aesthetic appeal. But with a myriad of steel building materials and supplies available, how do you determine which one suits your specific needs the best? Let’s delve into the world of steel framing systems and explore the top contenders, weighing their pros and cons to guide your choice.

Understanding the Basics of Steel Framing Systems

Steel framing systems are integral to modern construction, offering strength, durability, and flexibility unmatched by traditional building methods. But with various types available, selecting the optimal framing system for your project requires careful consideration. Here are four of the most prevalent steel framing systems to consider:

1. Conventional Steel Framing

Conventional steel framing is the most traditional form, often employed in large-scale industrial or commercial projects. This system involves assembling a framework of columns and beams made from structural steel. Its robust nature makes it ideal for buildings that need to withstand significant loads.

**Pros:**

– Exceptional durability and strength.

– Suitable for buildings with complex and unique architectural designs.

**Cons:**

– Higher material and labor costs.

– Longer construction timelines due to the complexity of the assembly.

2. Lightweight Steel Framing

Lightweight steel framing is an increasingly popular choice for residential and small commercial projects. It uses cold-formed steel sections that are lightweight yet strong.

**Pros:**

– Cost-effective for small projects.

– Faster and easier to assemble.

**Cons:**

– Not suitable for buildings requiring high load-bearing capacity.

– Limited to smaller scale projects.

3. Modular Steel Framing

This system involves prefabricated steel components that are assembled on-site. Modular steel framing is revolutionizing industries due to its efficiency and environmental benefits.

**Pros:**

– Significantly reduces construction time.

– Minimal on-site waste, offering environmental benefits.

**Cons:**

– Design customization may be limited.

– Requires careful planning for transportation of modules.

4. Panelized Steel Framing

Panelized steel framing involves pre-constructed wall panels that are quickly installed onsite. This system is prevalent in fast-paced construction environments.

**Pros:**

– Quick installation and reduced labor costs.

– Enhanced accuracy and quality control in the factory setting.

**Cons:**

– Limitations on design flexibility.

– Transportation and lifting equipment required for large panels.

Factors to Consider When Choosing a Steel Framing System

When deciding which steel framing system best meets your needs, it’s essential to assess several critical factors:

Project Scale and Design Complexity

For large, intricate projects, conventional steel framing provides the flexibility and load-bearing capacity required. Conversely, for smaller, less complex structures, lightweight or panelized framing systems may be more appropriate.

Budget Constraints

Evaluating your budget is crucial. Conventional framing tends to be more expensive due to material costs and longer construction times. If cost efficiency is a priority, modular or lightweight framing could serve as preferable alternatives.

Timeframe and Construction Speed

If time is a critical factor, modular and panelized systems offer the advantage of rapid assembly. These systems streamline the construction process, substantially reducing project completion times.

Environmental and Site Considerations

Consider the environmental impact and site-specific conditions. Prefabricated and lightweight systems minimize on-site waste, providing a more sustainable solution. Assess site accessibility for transport and the lifting of materials.

Availability of Steel Building Design Services

Engaging professional Steel Building Design Services can ensure your project meets regulatory compliance and design specifications. Experienced designers can provide insights into optimizing the chosen framing system, aligning it with building codes and standards.

Conclusion: Your Ideal Steel Framing System Awaits

Selecting the ideal steel framing system is nuanced, influenced by project size, budget, timelines, and environmental concerns. Whether you choose a conventional, lightweight, modular, or panelized system, aligning your needs with the respective advantages and disadvantages will drive successful outcomes. Remember, investing in comprehensive Engineered Drawings for Steel Framing ensures precision and quality in your construction project.

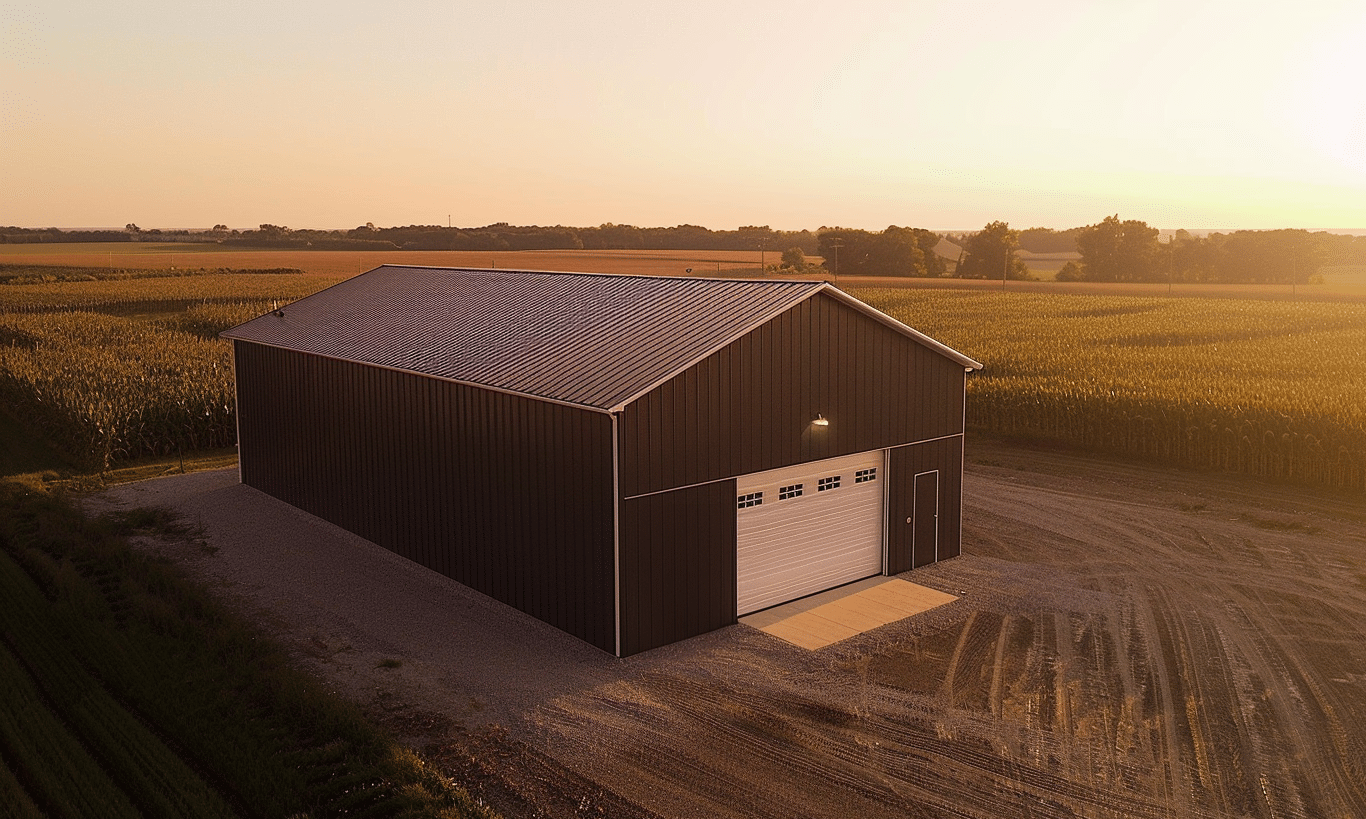

As you ponder the vast landscape of steel framing choices, visualize how these systems can frame your future project, providing the backbone of your architectural vision. For expert advice and comprehensive resources on steel building materials and supplies or to explore Steel Siding Options, consult with industry professionals for tailored solutions.