Enhancing Durability: The Role of Metal Building Coatings

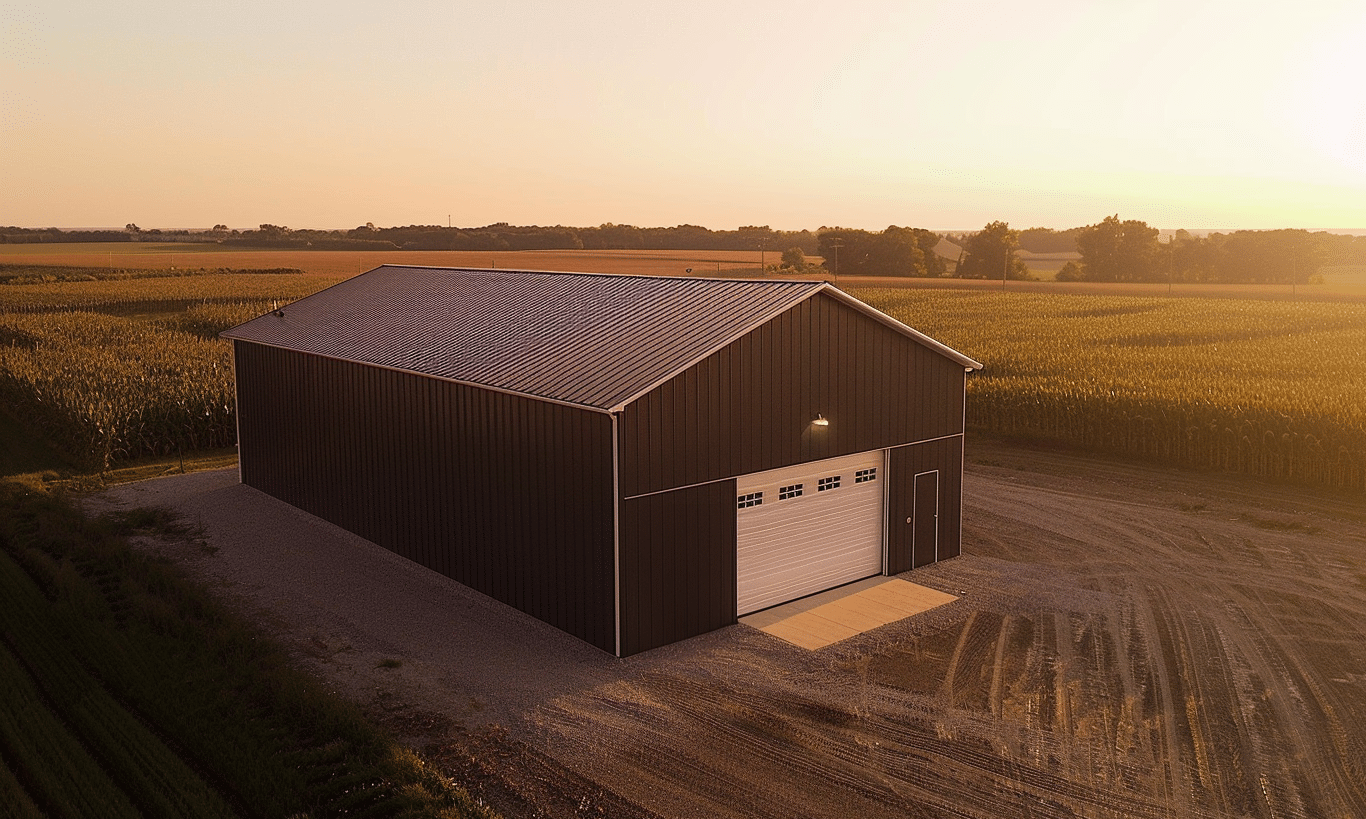

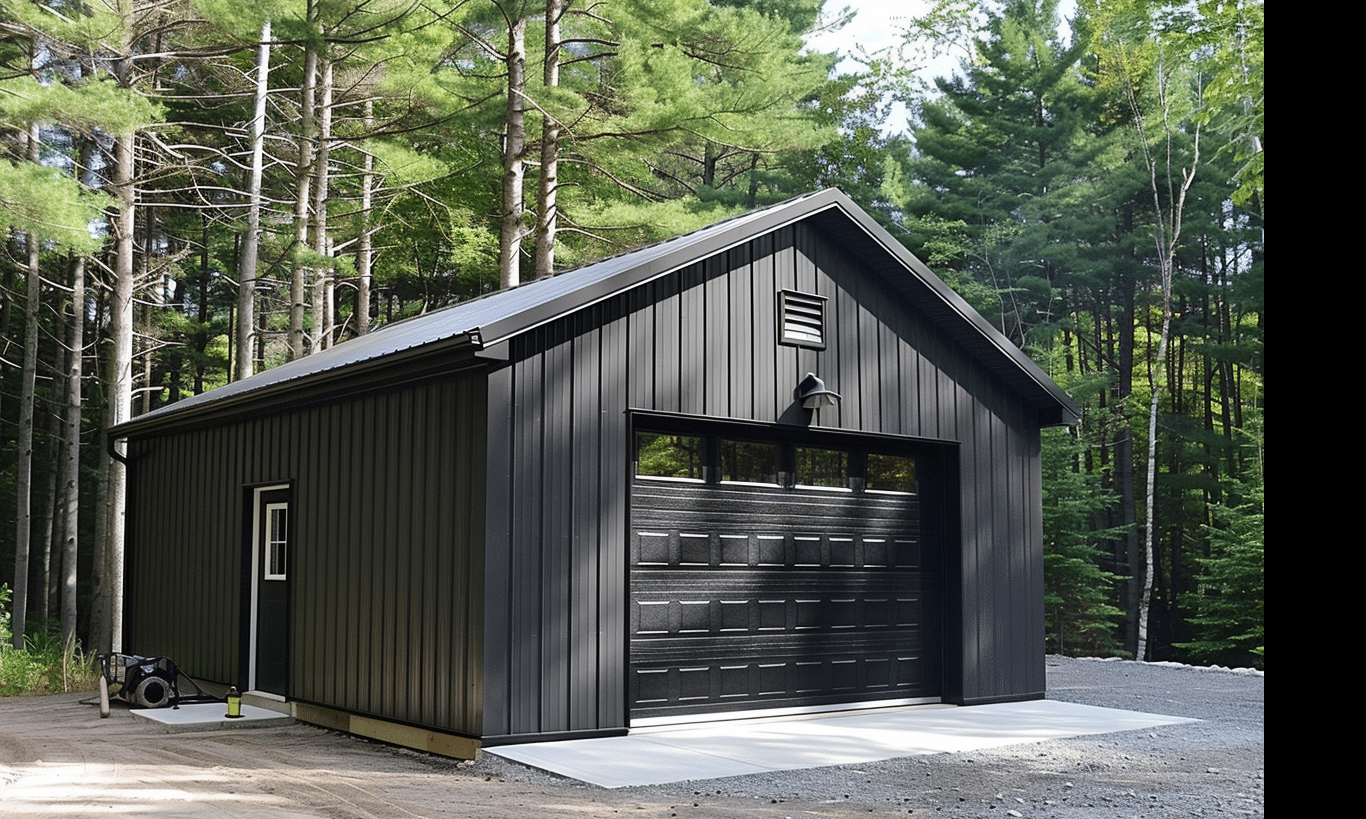

Imagine standing in front of your newly assembled metal building, feeling accomplished as the structure glistens in the sunlight. You’ve invested time, energy, and resources into creating something robust and long-lasting. But have you considered the role of proper paints and coatings to enhance its durability? Just as a knight’s armor protects against the elements, the right metal building coatings shield your structure from environmental wear and tear, ultimately preserving its longevity.

The use of high-quality paints and coatings is paramount in maintaining the structural integrity and aesthetic appeal of metal kit buildings. With the array of options available, it’s crucial to make informed decisions that will benefit your metal building in the long run. Let’s delve into how the right coatings can make all the difference.

The Importance of Metal Building Coatings

From minor scratches to significant corrosion, metal buildings face numerous challenges over their lifetime. Without adequate protection, even the sleekest designs can rapidly degrade. Metal building coatings act as a barrier against these adversities, offering both functional and aesthetic benefits. Coatings can help protect against rust, moisture, UV rays, and even physical damage.

The history of metal buildings reflects a journey of evolution in design and technology. Over time, the industry has embraced advanced protective solutions, recognizing their essential role in prolonging a building’s life span.

Types of Coatings for Metal Buildings

Understanding different types of metal building coatings is central to making the right choice. Much like selecting a gourmet meal from an extensive menu, this decision can significantly impact the final outcome. Let’s explore the primary types of coatings available for metal buildings:

1. Epoxy Coatings

Epoxy coatings are renowned for their durability and strong adhesion, making them ideal for industrial settings. They form a hard, protective layer that resists chemicals and abrasion. These coatings are typically applied in areas subject to heavy use or exposure to harsh elements.

2. Polyurethane Coatings

Offering more flexibility than epoxy, polyurethane coatings are another popular choice for metal structures. They provide excellent UV resistance and weather ability, making them suitable for outdoor applications. Their glossy finish also enhances aesthetic appeal, much like a high-quality varnish on fine wood.

3. Acrylic Coatings

Acrylic coatings are appreciated for their ease of application and cost-effectiveness. They provide moderate protection against environmental factors and are often used for aesthetic purposes. While not as durable as epoxy or polyurethane, they are eco-friendly and ideal for less demanding applications.

How to Choose the Right Coating

Choosing the right coating is akin to making sensitive financial investments. It demands a thorough consideration of various factors. Here are some key aspects to contemplate:

**#Environment:** The local climate plays a pivotal role in your decision. Buildings in moisture-rich areas, for example, require coatings with superior rust and corrosion resistance.

**#Usage:** Consider how the building will be used. Industrial metal kit structures, such as a metal shed storage building, require heavy-duty coatings.

**#Budgets:** High-quality coatings can be a significant investment. However, the upfront costs often lead to long-term savings by reducing maintenance and repair needs.

**#Aesthetic preferences:** The visual aspect should not be underestimated. Choose coatings that complement your design vision while providing the necessary protection.

Application Techniques for Optimal Results

The application process is critical. Even the most expensive coating can fail if applied improperly. Here are steps to ensure a job well done:

**#Surface preparation:** The surface must be clean, dry, and free of contaminants. Sandblasting or chemical cleaning may be necessary for removing rust or old coatings.

**#Correct equipment:** The proper tools play a vital role in achieving a uniform application. From brushes to sprayers, using quality equipment ensures better adherence and a smoother finish.

**#Environmental conditions:** Temperature and humidity affect how coatings are applied and cured. Follow the manufacturer’s guidelines to optimize performance.

**#Multiple layers:** Often, multiple coats are needed for maximum protection. Allow each layer to cure fully before applying the next for a flawless finish.

Maintenance and Longevity

Even though your newly coated building seemingly defies time, regular maintenance is crucial. A strategic maintenance plan will ensure that your metal building coatings continue to perform optimally. Consider periodic inspections to catch any signs of wear early. Quick repairs of chips or scratches prevent further damage and save on larger expenses later.

Additionally, maintaining your building in Ontario requires observing the specific needs unique to the region’s climate. Metal buildings, like those discussed by Ontario steel construction, can benefit from a regional approach to maintenance.

Conclusion

In conclusion, the proper selection and application of metal building coatings are vital in enhancing the durability and longevity of your metal kit structures. By investing both time and resources into understanding the diverse options available and adhering to optimal application techniques, you’ll protect your investment for years to come.

So the next time you stand proudly before your metal building, consider its protective shield. Much like polish on fine leather boots, the right coating ensures that your structure is not only resilient but also a sight to behold. Embracing these insights can lead to a smarter, more durable future for your building ventures, a goal that Your Building Team strives to support through every step. Just like the security recommendations further explored by SafeWise, a comprehensive approach ensures safety and durability go hand in hand.