Understanding the Landscape of Metal Building Assembly

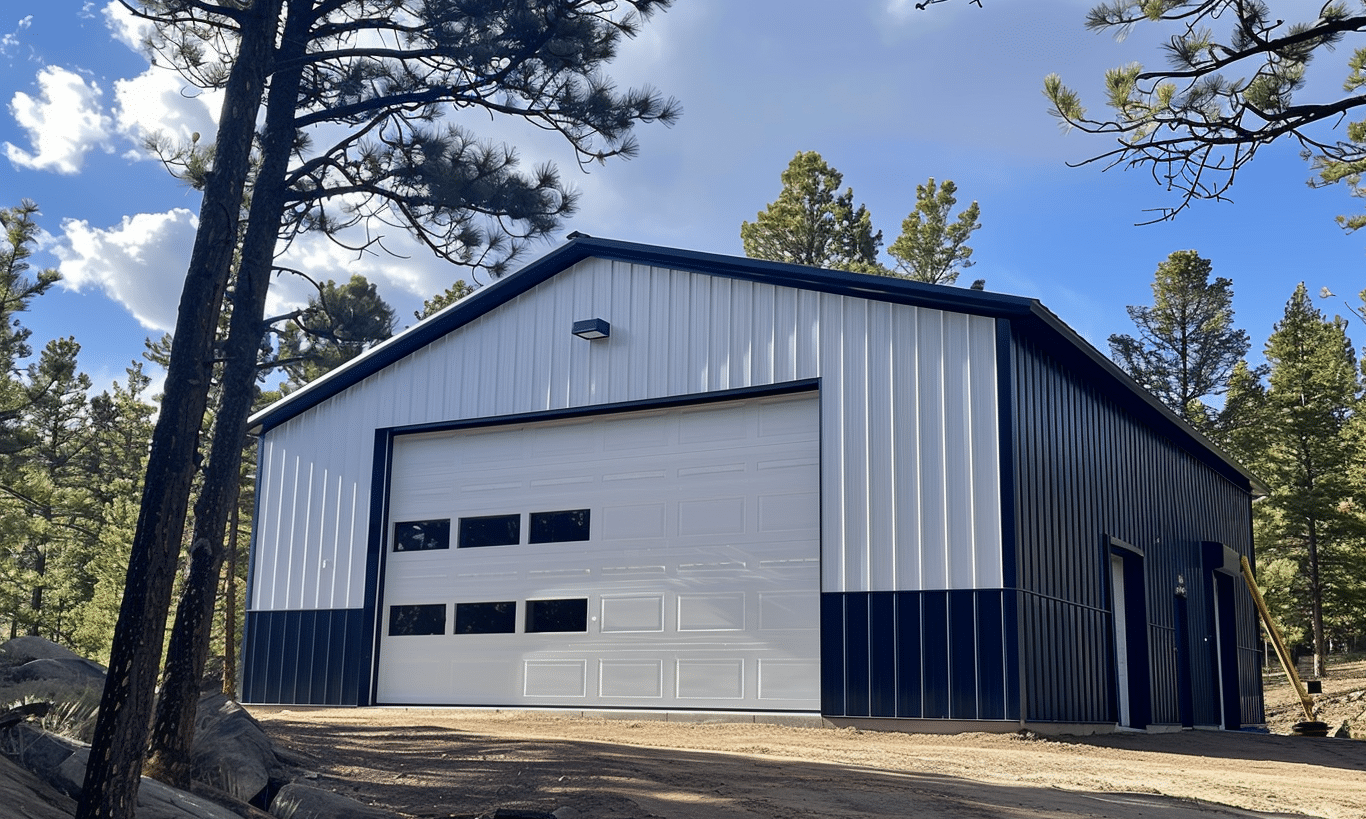

Building with steel may seem as straightforward as snapping together a model airplane kit. However, when you dive into the realm of metal building assembly, you’ll find that it’s akin to piecing together a colossal, life-sized jigsaw puzzle. From deciphering complicated blueprints to maneuvering hefty industrial components, challenges abound. For the unprepared, these obstacles can turn a promising project into a permanent work-in-progress. Luckily, by knowing these metal building assembly challenges firsthand, you can arm yourself with strategies to overcome them.

Navigating Planning Pitfalls

When we picture creating a structure from scratch, the mind often races to images of hammering nails or riveting bolts. Yet, much like a chef meticulously planning a grand feast before the first onion is diced, the majority of work in metal building assembly occurs long before lifting the first steel beam. But where do potential pitfalls arise?

### Ensuring Precise Measurements

Picture this: you’re halfway through assembling your Commercial Steel Buildings, putting all components perfectly in place, only to find that two key sections don’t align. Alas, a common scenario faced due to imprecise measurements. Metal building assembly relies heavily on precision—from length and width to every minor bend and bolt. Even a minor miscalculation can lead to significant setbacks.

#### Overcoming the Problem

Begin by double-checking all blueprint schematics and measurements before any physical work is done. Engaging with trusted metal building manufacturers in Ontario can provide insights into frequently encountered mismatches. Pre-assembly workshops or on-site test fittings may add an extra layer of security to avoid surprises later on.

Weather Woes and Environmental Effects

Much like an artist choosing the right canvas, selecting an optimal environment for assembly can immensely impact the quality of your build. Elements such as rain, wind, and extreme temperatures can wreak havoc on timelines and material integrity.

### Facing Unpredictable Weather

Consider assembling a structure similar to built-to-last Industrial Metal Building Kits. These must withstand the harshest elements. With the Canadian climate being notoriously unpredictable, fluctuating weather conditions during installation can not only delay progress but affect the structural integrity of your build too.

#### Strategies for Success

Monitor long-term weather forecasts pre-assembly and plan contingently. Having precautions like weatherproof tarps or adjustable work schedules can help mitigate these effects. Collaborating with experienced builders like Your Building Team ensures projects are steered with weather adaptability in mind.

Resource Management and Human Element

Unlike stories from This Old House of overcoming all odds with sheer grit, assembling metallic giants demands not only talent but significant resource management acumen.

### Developing Team Coordination

Creating a seamless dance in a bustling assembly site, where everyone from engineers to welders knows their steps, is easier said than done. Miscommunication not only wastes time but translates into rework and, sometimes worse, structural mishaps.

#### Building the Dream Team

Implement daily planning meetings ensuring every professional is on the same page. Assign specific tasks with clear deliverables. Investing in team training around new methodologies or tools enhances fluidity and coordination on the ground.

Material and Equipment Delays

Ever lunch at your favorite diner only to find they’re out of your beloved dessert? Imagine experiencing this, but now on a construction site. Material and equipment delays can systematically halt progress.

#### Lessons in Adaptability

Cultivate relationships with reliable suppliers and set up a buffer schedule. To tackle unforeseen disruptions, keep versatile equipment available on standby. Leveraging local resources, such as trusted metal building manufacturers Ontario, can provide quicker replenishments and minimize delays.

Technical Glitches and Assembly Hiccups

When your car won’t start, a quick jump gets you back on the road. However, with technical installation in metal projects, solutions aren’t always as straightforward.

Understanding Design Complexity

Gone are the days of simple barn blueprints. Today, advancements and architectural creativity present designs that can be both a blessing and a curse. The blending of intricate designs with practical assembly often results in complications.

### Addressing Technical Delays

Clear communication and collaboration with design teams during initial phases are critical. Consider employing simulation software to foresee any practical hurdles during the blueprint stage. Consulting experts from Commercial Steel Buildings often brings invaluable insight into foreseen design adaptations.

Troubleshooting Equipment Failures

Failures happen when we least expect them, similar to a surprise flat tire on a road trip. From welding machines fizzling out to cranes serving as overgrown paperweights, equipment failures are constant hurdles.

#### Key Takeaways

Regular maintenance and checks are crucial. Establish contingency plans and have backup equipment readily available. Engaging with experienced construction companies and teams is vital, as they provide polished procedures for swift resolutions, such as working with Your Building Team.

Embracing and Conquering Assembly Uncertainties

Construction isn’t just about raw materials; it’s a harmonious blend of art and science. Embracing the challenges in metal building assembly means anticipating setbacks and having a game plan set aside. Whether you’re assembling custom Commercial Steel Buildings or utilizing efficient Industrial Metal Building Kits, encountering challenges should no longer be a mere surprise, but an expected part of the journey.

Looking ahead, aim to transform potential pitfalls into testimonies of success. Let any challenge become your foundation for learning and adaptability. Remember, every monumental skyscraper began as metal and dreams. With preparation and persistence, your project can reach those same heights.