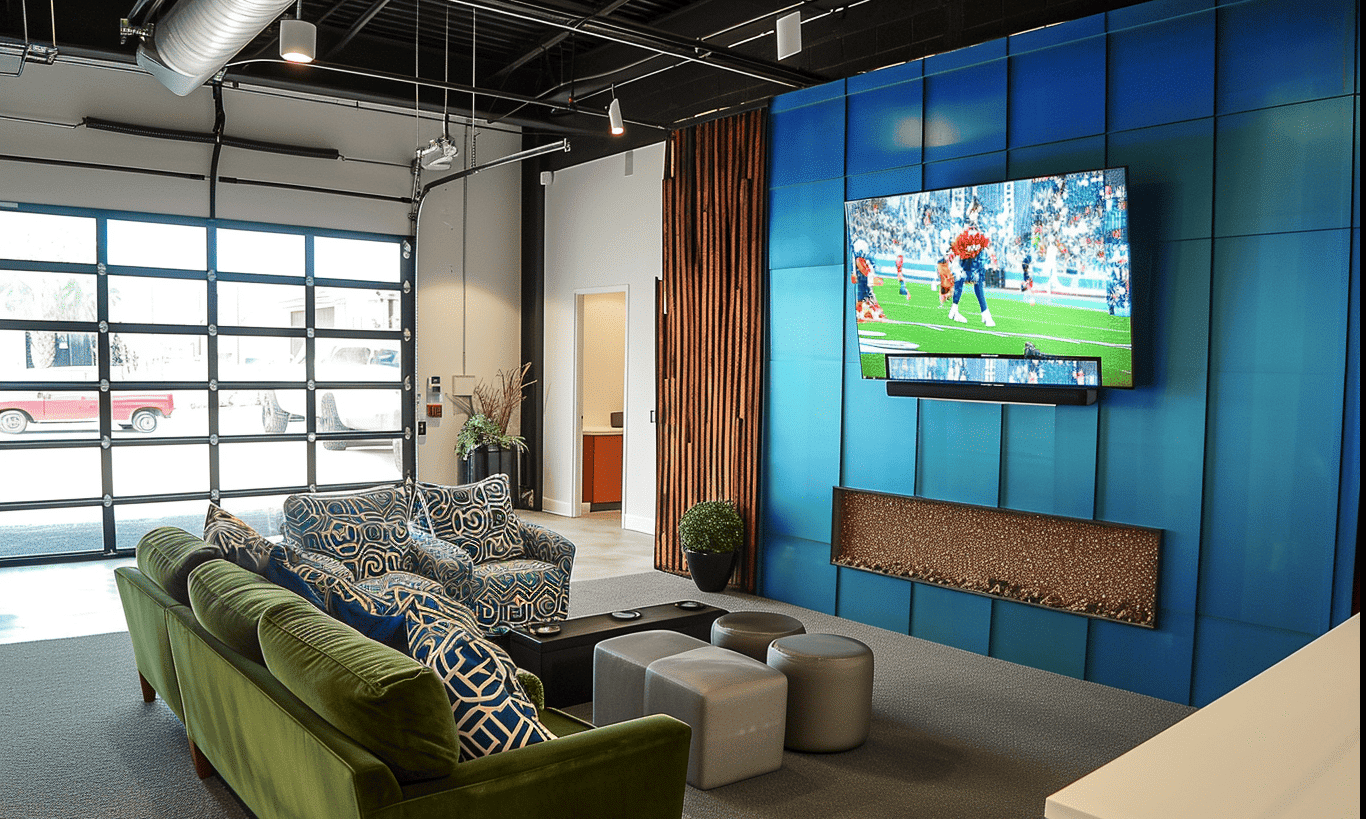

Steel is the backbone of many construction projects in Canada and worldwide. From skyscrapers in Toronto to quaint steel-framed homes in Ottawa, the reliability of steel materials fundamentally determines structural integrity and safety. However, not all steel is created equal, and the importance of material quality control cannot be overstated. With various grades and coatings available, ensuring the quality of steel used in any project is paramount.

Understanding Steel Grades: Why Do They Matter?

Steel grades are classifications that provide essential information about the chemical composition, mechanical properties, and intended use of steel. Different projects require different steel grades, and ensuring the correct one can mean the difference between success and disaster.

How Are Steel Grades Determined?

Steel grades are determined by standards organizations such as the American Iron and Steel Institute (AISI) and the Canadian Standards Association (CSA). These institutions establish clear guidelines concerning properties such as tensile strength, ductility, and yield stress. Each grade serves various applications, from residential construction to heavy industrial use. But why does it matter?

Using the wrong grade can compromise **steel building safety and compliance**. For instance, using a lower-grade steel in high-stress situations can lead to structural failures, potentially causing catastrophic events. Therefore, it’s crucial to verify steel grades meticulously, implementing robust **material quality control** measures to avoid pitfalls.

Coatings: Your First Line of Defense Against Corrosion

When steel is exposed to the elements, rust and corrosion can quickly set in, significantly shortening its lifespan. Protective coatings are pivotal in extending the durability of steel structures and ensuring long-term performance.

Common Types of Coatings

1. **Galvanizing**: This involves applying a protective zinc coating to steel to prevent rusting. Commonly used for outdoor structures, galvanizing offers excellent rust resistance.

2. **Epoxy Coatings**: Known for their strong adhesive properties, epoxy coatings provide excellent protection against moisture and chemicals.

3. **Powder Coating**: A dry powder is applied to metal surfaces and then cured under heat. This type of coating offers a hard finish that is tougher than conventional paint.

Ensuring that these coatings meet the relevant standards is an integral part of **material quality control**. Faulty or compromised coatings can reduce a structure’s lifespan and safety, potentially leading to increased maintenance costs and structural instability.

Advanced Techniques in Material Quality Control

Technological advancements have led to new and improved methods for verifying material quality. From spectroscopic analysis to advanced imaging technologies, these methods have revolutionized the **material quality control** landscape.

Spectroscopic Analysis

This technique involves analyzing steel’s chemical composition through light spectrum analysis. It helps identify impurities that could compromise structural integrity. By ensuring that only the highest quality steel is used, spectroscopic analysis is a vital step for **quality steel building supply**.

Non-Destructive Testing

Non-destructive testing (NDT) techniques allow for assessing a material’s structure without altering it. Methods such as ultrasonic testing, radiography, and magnetic particle testing help detect internal flaws that might not be visible externally.

Ensuring Compliance with Industry Standards

Construction and engineering firms in Canada must adhere to strict guidelines to ensure safety and quality. Familiarity with the Code of Standard Practice for Steel Buildings and Bridges is crucial. It outlines best practices, providing a framework for maintaining **steel building safety and compliance**.

Moreover, regular inspections are paramount. To learn more about inspection protocols, explore Inspection Essentials Key Areas to Review for Steel Building Compliance.

Conclusion: Quality Control is Non-Negotiable

The importance of stringent **material quality control** in steel construction cannot be overemphasized. From verifying steel grades to choosing the right protective coatings, each step is crucial in ensuring the longevity and safety of any construction project. It not only ensures compliance with industry standards but also safeguards against potential hazards and costly repairs down the line.

Remember, in steel construction, quality is a promise you can see and feel — a promise that safeguards lives and investments. For more insights and answers to common queries, check out our Steel Building FAQs section.

Ensuring quality starts from the ground up, quite literally, and at the core lies the steadfastness of good old steel, reliable and enduring as ever. In the world of construction, that’s a promise always worth keeping.