Embarking on the journey to assemble your very own metal building kit feels much like piecing together a complex yet rewarding puzzle. The satisfaction of watching a functional and sturdy structure rise from a flat-pack design is akin to artistic creation. As you delve into this process, the terms, “assembling metal building kits,” might initially seem daunting—but worry not, as you are not alone in this venture.

Assembling metal building kits can be straightforward if you tackle the project with a plan in mind, ensuring every bolt, panel, and beam finds its place. Here, I’ll guide you through each step, helping you not only build but also enjoy the process from start to finish. Ready to go from foundation to grand unveiling? Let’s dive in to transform your plot of land into a magnificent structure.

Unpacking Your Kit: All You Need to Get Started

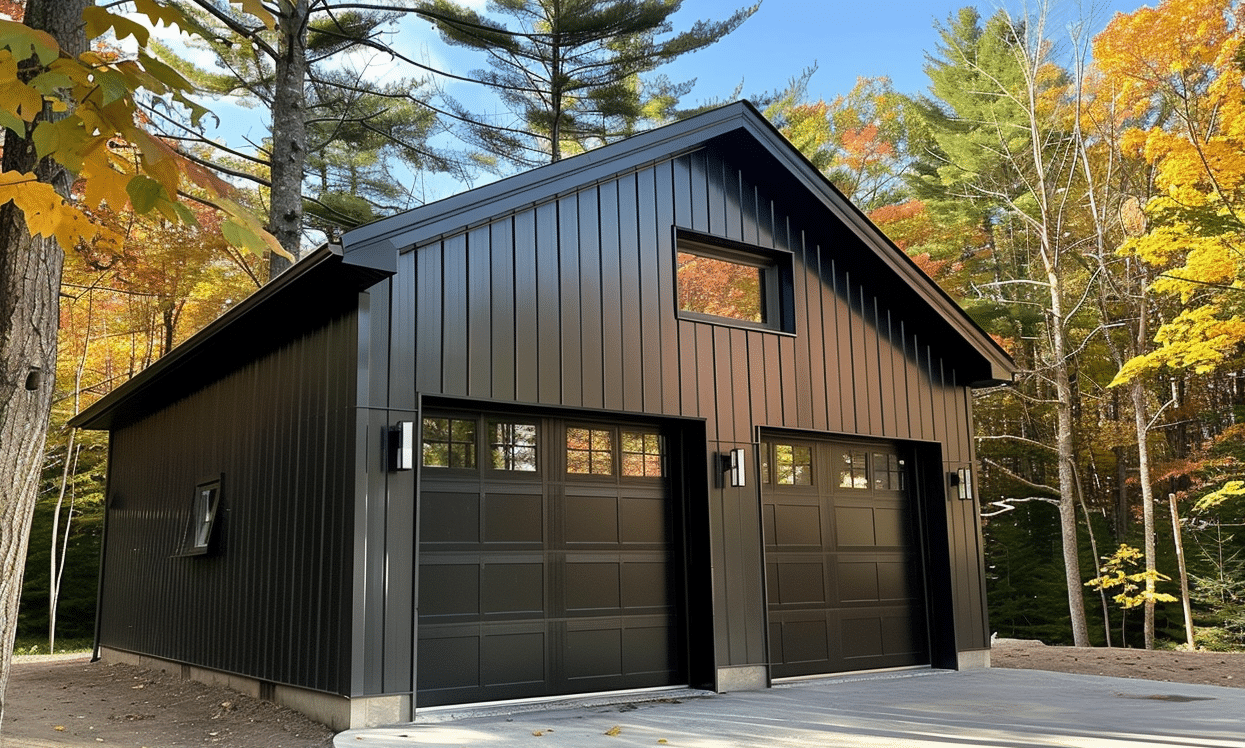

Imagine you’ve just received a kit for a large puzzle box, except each piece will come together to form your new workshop, garage, or perhaps an agricultural metal building. The key is staying organized right from the start.

Inventory Check

Before you dive into the nuts and bolts, conduct a thorough inventory check. This ensures you have all components at your disposal and can address any missing pieces with your supplier, such as Your Building Team, right away. The inventory will typically include the building frame, panels, bolts, screws, and any finishing items recommended for your specific build.

Setting the Foundation

A solid foundation is critical when assembling metal building kits. It’s not just about stability; it’s about future-proofing your building for years of use. Ensure your site is well-prepared—either a concrete slab or anchoring system appropriate for the kit’s footprint and weight. Follow local building codes and regulations, as these vary from region to region.

Gathering Tools and Safety Gear

Like a chef in the kitchen, having the right tools ensures a smooth assembly process. Essential tools typically include wrenches, drills, measuring tapes, and safety gear like gloves and goggles to protect yourself during construction.

Step-by-Step Assembly Guide

Now that you’re set with your materials and tools, let’s proceed with the assembly of your metal building kit.

1. Erecting the Frame

The heart of your building lies in its framing. Start erecting the main structural steel frames, which often resembles the ribs of an animal, giving the project shape and strength. Carefully follow the provided instruction manual, ensuring that every part is bolted securely.

2. Attaching the Panels

Once your skeletal structure stands tall, it’s time to cover it with panels. These often comprise sturdy metal sheets that form the walls and roof. Attach these panels securely to protect against the elements and add durability to your structure.

3. Insulation and Energy Efficiency

Insulation is not just about comfort—it’s about building longevity and efficiency. You might choose to include an insulation layer that aligns with Energy Star Canada standards, optimizing your building for energy conservation.

4. Finishing Touches

It’s the little things that often pull the entire structure together. Ensure you install all finishing components like window frames, doors, and any bespoke features such as vents or additional external covering that might be necessary depending on your climate and usage.

Tips and Tricks for an Efficient Assembly

Let’s delve into some insider knowledge—those nuggets of wisdom that have helped countless builders like you.

Patience and Precision

The assembly process requires a steady hand and patience. Each phase should be double-checked for alignment and stability, so take your time to ensure everything is in its rightful place before moving to the next step.

Embracing Teamwork

Having an extra pair of hands can be invaluable. Whether it’s family, friends, or hiring a small team, teamwork accelerates the assembly process and improves safety, especially when lifting heavy frames or aligning large panels.

Leveraging Local Expertise

When in doubt, reach out to local experts. Areas within Ontario or elsewhere often have contractors familiar with the nuances of local building code and environmental conditions that might affect your metal building.

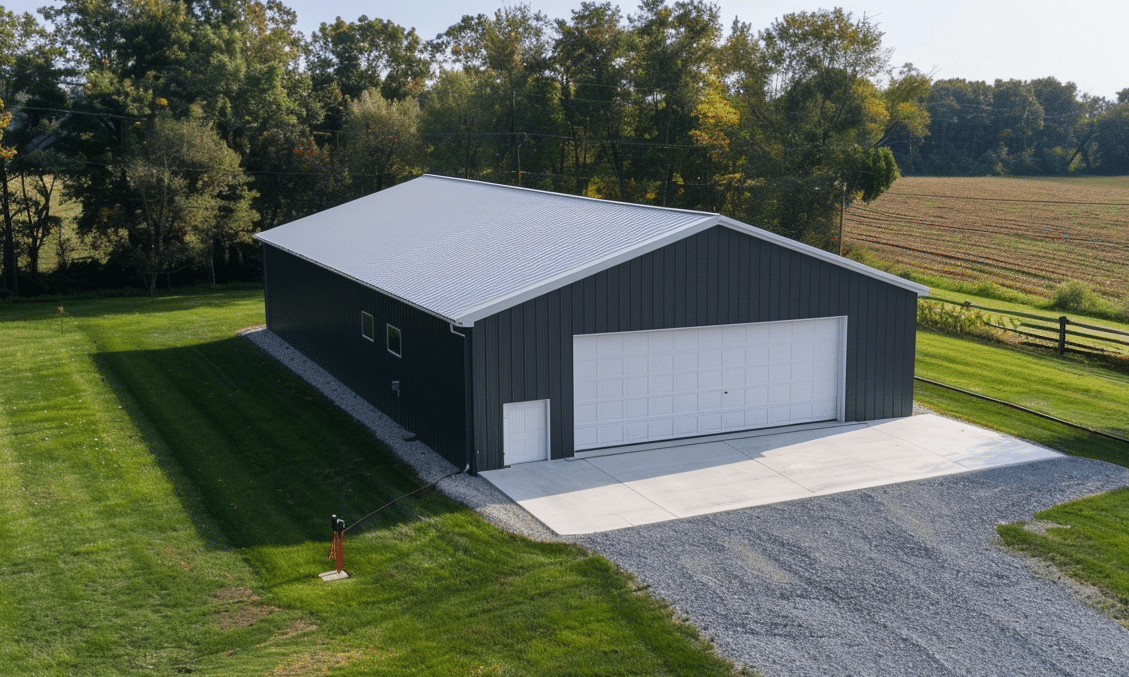

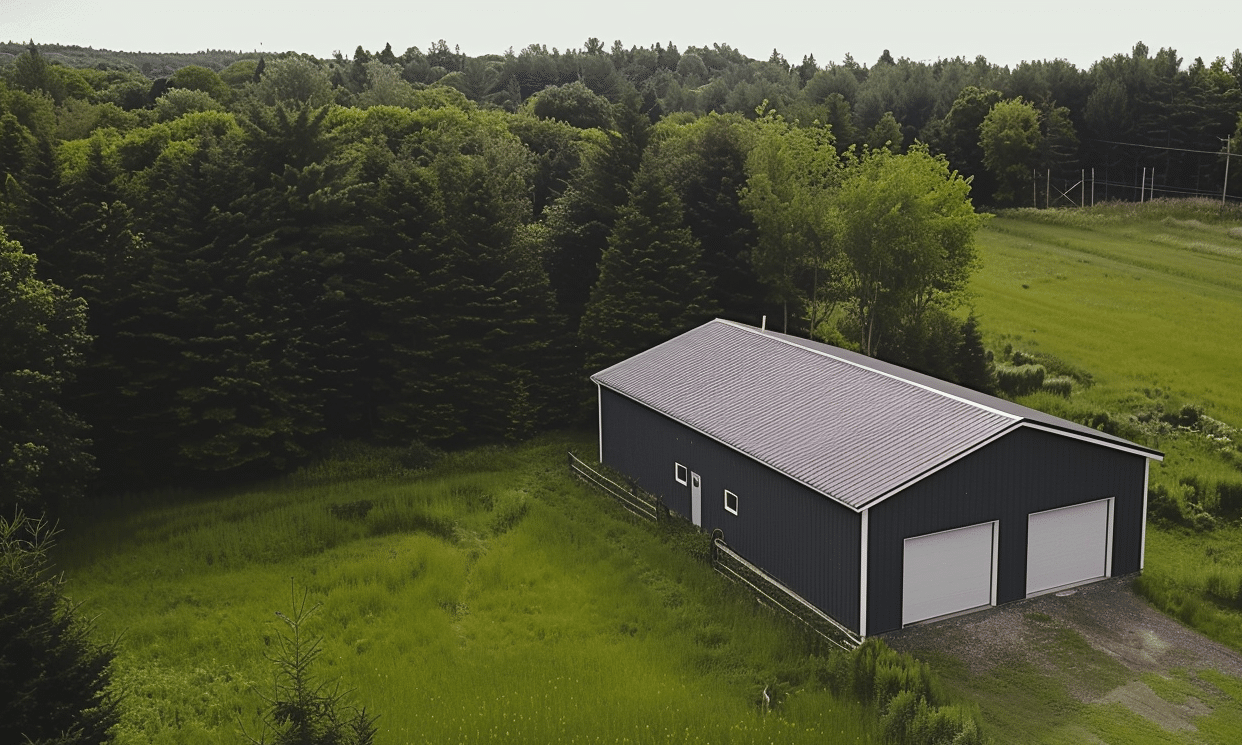

Bringing It All Together

Congratulations! The effort invested into constructing your metal building kit is evident in the majestic structure now standing before you—remarkable for its durability, resilience, and beauty. Whether intended for agriculture, workshops, garages, or other purposes, this is more than just a building. It represents innovation and is a testament to human ingenuity, a stable feature set to withstand the test of time.

Building enthusiasts and newcomers alike can appreciate the step-by-step method of transforming raw materials into a tangible asset. Just as every building tells a story, so does the labor and passion poured into these structures, making dreams come true, one bolt at a time.

In conclusion, by following this guide, you’ve not only assembled a building but crafted functional art—a shelter that’s as strong and reliable as any expression of your needs be it commercial steel buildings in Ontario or a serene agricultural retreat. Explore further options or connect with experts at Your Building Team to continue your journey into constructing superior agricultural steel buildings, tailored perfectly for your environment.