There is perhaps no more versatile, robust, and efficient way to construct a building than with a metal building kit. These kits provide all the necessary components to create durable and sustainable structures, whether for commercial garages, residential homes, or industrial facilities. Understanding the anatomy of a metal building kit—its key components and their purposes—can not only optimize your construction knowledge but also aid in making informed decisions when purchasing and maintaining your building.

The Backbone: Structural Framework

The heart of any metal building kit is its structural framework, which includes primary and secondary components crafted to form the skeleton of your structure. These constituents are engineered to bear loads and provide overall stability and shape.

Primary Components

Think of the primary components as the backbone of your metal building. These include rigid frames, columns, and rafters. Constructed from strong steel beams, they support the weight of the roof and walls, and resist the forces of nature, like wind and snow. The size and spacing of these elements vary widely depending on load requirements and the size of the building—just as the 24×30 steel building kit reflects a different configuration from a more compact 24×24 Metal Building.

Secondary Components

Secondary components, such as purlins, girts, and eave struts, act like the tendons and ligaments of a body, connecting major parts to one another and offering additional support. Purlins and girts work horizontally across the frame, providing lateral support and a fastening surface for roof and wall panels. Eave struts join the eave line, providing a smooth transition and uniform load distribution from roof to wall.

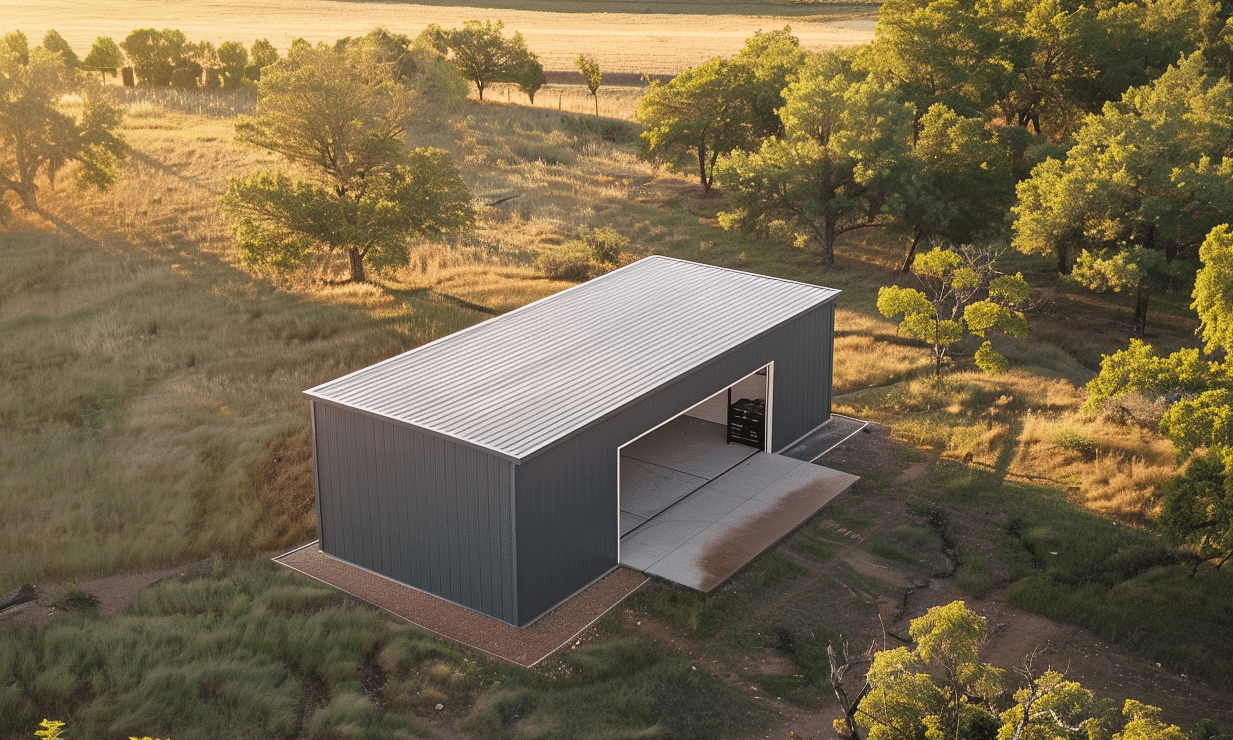

The Shield: Metal Panels

Opting for a metal building involves not merely erecting a skeleton but cloaking it in a protective layer—metal panels. These are the skin that safeguards the framework while contributing to the aesthetics and energy efficiency.

Roof Panels

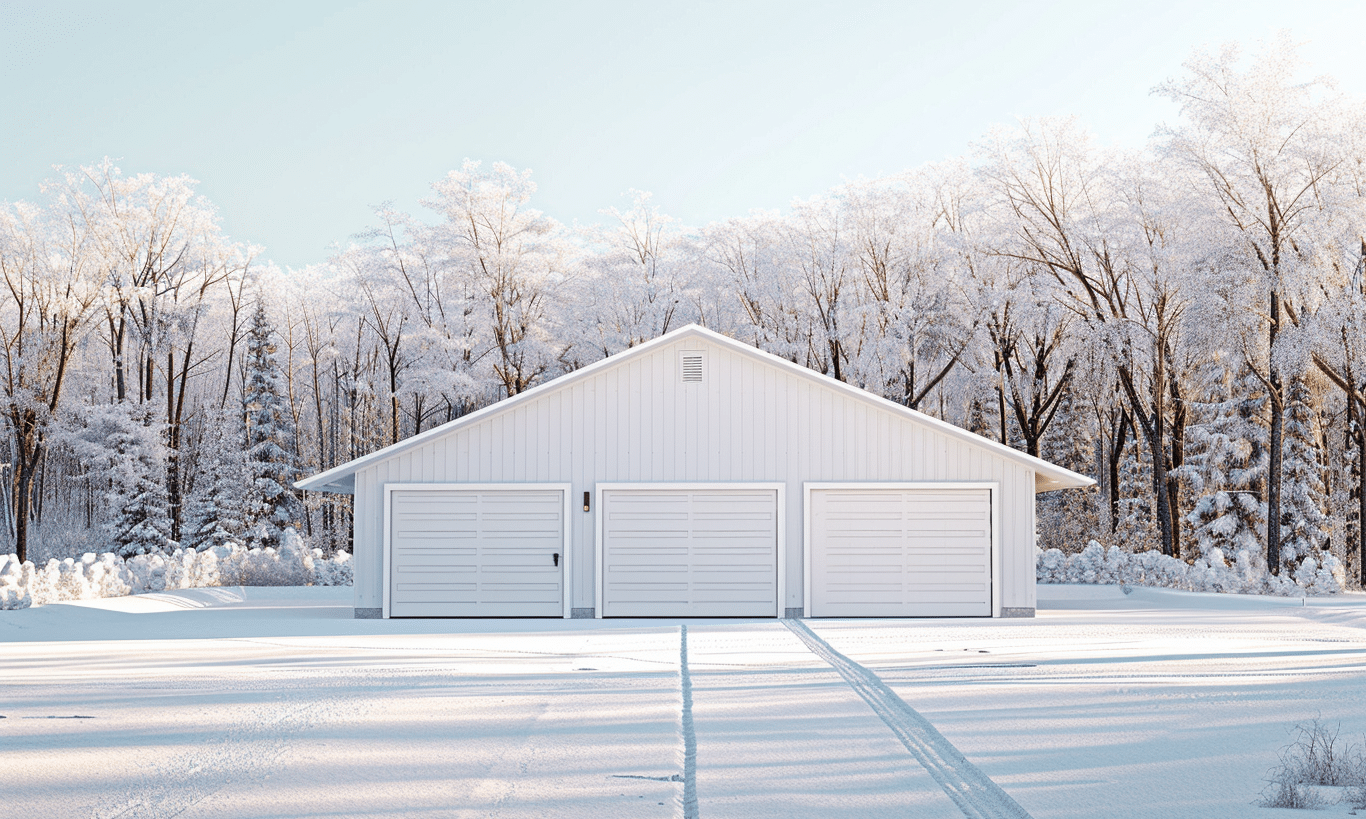

Roof panels are integral in ensuring longevity and insulation for your structure. Available in various profiles and gauges, these panels are designed to enhance water runoff, resist corrosion and heat absorption. In the frigid and snowy environments of Ontario, steel building solutions are particularly apt due to their resilience and thermal efficiency.

Wall Panels

Wall panels, like a well-tailored suit, give a building its appearance and character. Crafted for durability and aesthetic appeal, these panels allow for custom finishes and innovations like insulation layers that might align with Canadian Living standards in energy efficiencies, providing warmth in cold climates.

The Connectors: Fasteners and Joints

What ties a metal building together as a cohesive unit are the various fasteners and joints. Think of these as the nuts and bolts—literally—that hold the individual components together, transferring loads and stresses in a uniform and predictable manner.

Bolts and Screws

High-strength bolts are typically used in primary frameworks, providing critical connections for beams and columns due to their excellent load-carrying capacity. Conversely, self-drilling screws are predominant in secondary components and panels, offering ease of installation without sacrificing strength.

Sealants and Insulation

Sealants and insulation play a vital role in bridging small gaps between the elements, enhancing water tightness and energy efficiency. These minor yet crucial components prevent leaks, reduce thermal bridges, and ultimately contribute to the overall durability of the building.

Navigating Add-ons: Doors, Windows, and Extras

Just as accessories can make or break a wardrobe, the final touches in a metal building kit can personalize and enhance functionality. These include tailored doors, windows, internal partitions, and even specific load-bearing considerations for machinery or loft spaces.

Doors and Windows

Selecting the right doors and windows is essential for ventilation, egress, and natural lighting. Roll-up doors, personnel entry doors, and various window styles must be chosen based on specific needs—from accessibility in a 24×30 steel building kit to aesthetic desires in residential spaces.

Future Modifications

The true beauty of metal building kits is their adaptability. As your needs evolve, additional components can be incorporated with relative ease. The initial design might suffice for a decade, but the inevitability of change ensures ongoing interest in Metal Building Maintenance and modifications for optimized utility.

In conclusion, the anatomy of a metal building kit is like that of a precisely crafted instrument, with each component playing its part in creating a harmonious final piece. Understanding these key components—from structural frameworks and panels to essential fasteners and thoughtful add-ons—not only empowers you in their initial assembly but ensures they remain an asset for years to come. With insightful choices, maintenance, and potential enhancements, the metal buildings of today lay the foundation for a sustainable future. By diving into the endless potential these kits offer, much like unfolding a complex IKEA manual, you’ll not only cultivate knowledge but forge a path in constructing your ideal environment with elegance and longevity.